#nexosound

#nexolife

Part II

Probably the most distinctive high-end sound reinforcement product ever launched, the slender silver lines of NEXO’s tangent array found their way into rental inventory all over the world, including working five years for SSE on one of the most famous of all live venues, the Pyramid Stage at the Glastonbury Festival.

“Once we had the patent for the Hyperbolic Reflector Waveguide, and we saw the success of the GEO S8, we could use it in other products,” recalls François Deffarges, Director of Engineering Support at NEXO. “In 2002, we unveiled the GEO T flagship arrayable system.

“We called them tangent arrays, rather than line arrays. We found we could create two almost identical boxes, containing the same components but with two different wavefront angles, 5° and 30°. When you arrayed these boxes together and set 17.5° between them, then the wavefronts would have tangential directivity.

“The HRW enabled us to build cabinets with a range of curvature from 0° to 30°, and eventually 45°, then 90°. The competition at the time did not have that ability. If a stage needed to be clear of frontfill, all the sound could be delivered by the cluster, all the way to the front row. We defined a U shape, which meant the cluster could cover from negative 100m to positive 100m including 0, from a single location.”

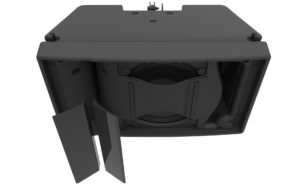

The development process for the GEO S8 yielded another key component, the Configurable Directivity Device (CDD) which was patented by NEXO’s Eric Vincenot in 2001. The HRW provided an advantage in terms of vertical coverage; with the CDD, the NEXO designers addressed the horizontal coverage.

“Horizontal coverage is challenging,” explains Deffarges. “When a system reaches from 80 m to 0 m, it is obvious that you need less coverage at further distance and more coverage at less distance. Horizontal coverage is governed by the horn expansion. Historically, we’ve seen conical horns, exponential horns, constant directivity horns and so on. Correctly applied expansion ensures that the frequency response over the coverage remains as constant as possible.

“A horn has two sections: the throat, and the expansion profile. We designed GEO S8 for 80° horizontal coverage, but we realised that, by inserting two flanges into the horn, we could widen the coverage and achieve 120°. This gave us the ability, unique at the time, to modify the horizontal dispersion characteristics. NEXO was the first manufacturer to do this, evidenced by our patent.”

The Configurable Directivity Device (CDD) is a diffraction slot used to control acoustic coverage across the non-coupling (horizontal) plane. The CDD applies user-adjustable bolt-on flanges to set the diffraction slot’s exit flare rate at either 80° or 120°. The same speaker cabinet reference can then produce a wide range of directivity features, from 60° or less (narrow coverage needed at long distances) to 120° or more (wider coverage needed at short distances). The flanges deliver a wide range of control over wavesource behaviour, which helps fill in any coverage gaps in the line array system.

“Good developments are all about asking yourself the right questions,” says Deffarges. “We could see a big advantage for our users to be able to have two different coverages from the one box, including the fact that the rental company doesn’t need to buy a purpose-built wide dispersion box for the bottom of the hang. Once we had the CDD flanges, the same speaker cabinet reference could produce a wide range of directivity features.”

This has become a signature of NEXO loudspeaker products, which can be seen in the latest releases, the P+ Series, which permits the user to interchange the horn flanges to deliver a variety of directivities – from the 60°x 60° that is provided as standard, to a 90°x 40° or an asymmetrical 50°- 100°x 40°. That is three references in one box, and then it can be used vertically or horizontally to get even more options. Not a lot of people realise that NEXO was the first manufacturer to build line array systems that could be used horizontally as well as vertically. “We believe that constant curvature arrays and line arrays are one family, whereas most other manufacturers regard them as two.”

Over the last twenty years, HRW and CDD have provided the design starting point for multiple NEXO product families, all recognised for their exceptional accuracy, consistent frequency and SPL coverage, as well as delivering an impressively close correlation between mathematical predictions and real-world results.