#nexosound

#nexolife

Part 4

NEXO has long had a stellar reputation for subwoofer design, one of the industry leaders in terms of innovative acoustic design. The company maintains a strong line-up of subbass products in its catalogue, giving its customers the maximum opportunity to tailor system performance to the application.

NEXO’s Director of Engineering Support François Deffarges recalls some of the patents, innovations, and other twists and turns in the company’s design trajectory. “Starting in the 80s, we were one of the first manufacturers to apply comprehensive science to this category of boxes, earning the know-how to do subwoofer design properly. And from the very beginning, we made a heavy investment in software, modelling, and measurement.”

Two decades ago, NEXO pioneered cardioid subwoofer technology, which allows the subwoofer frequencies to be controlled and directed like a laser beam. By emitting a secondary sound wave out of the back side of the subwoofer that is equal to and opposite every sound wave which emanates from the front, the sound is cancelled out in the rear, and is in fact increased in the front.

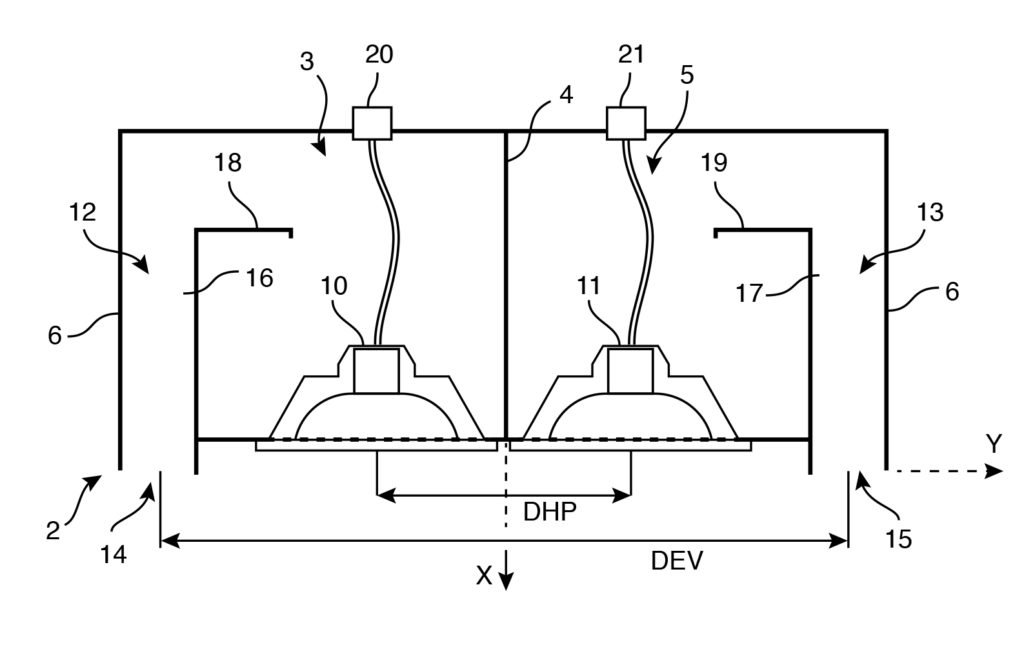

“Our first big innovation was the CD12; launched as the partner sub for the GEO S8, this was a ‘native’ cardioid subwoofer design, sometimes called a hyper-cardioid. When we released the larger double-18” CD18, it was one of the loudest subs on the market.” However, the CD Series could not be used in omnidirectional mode so, in 2007, NEXO filed a new patent for RaySub technology and launched the RS15 and RS18, the first subs in the world to offer cardioid and omnidirectional pattern in a single cabinet.

“Sub cabinets are usually exclusively omnidirectional or cardioid. When cardioid pattern is needed, it requires a specific cabinet design, or the arrangement of various cabinets into front/rear configurations. Additionally, LF cardioid patterns are detrimental to efficiency. RS technology allows the use of a unique cabinet to produce omnidirectional pattern (the two low frequency drivers are set frontwards, and fed with the same audio signal) or directional pattern (the cabinet is rotated by 90°, and front and rear LF drivers are fed with 2 different audio signals).”

The RS15 and RS18 are still in the catalogue, and widely used around the world. But in 2011, with the development of the STM Series modular line array, NEXO moved in a different direction. “We wanted to use the same small footprint for all the STM modules so we decided that cardioid would become modular (which we could achieve by combining two units). This gave users the ability to do side to side, or omni, or back-to-back, so people could build up their own cardioid strategy.”

The STM S118 sub debuted another patented innovation. Licensed from a French university, and drawing on aeronautic shapes from jet engines, it allowed NEXO’s designers to introduce not a vent, but a nozzle: this is the concave shape that is present in the STM S118. Acoustic ducts or vents create turbulences (vortex) at very high air particle velocity. These can be so important that the air flow along the duct can be blocked, thus strongly limiting the maximum SPL output unless the duct cross section is significantly increased. The use of these patented nozzles as acoustics ducts with a concave cross- section allows NEXO designers to gain up to 6 dB over a conventional convex-profiled vent design.

After STM Series, NEXO moved onto the development of the GEO M family of compact and mid-sized line arrays. Forward thinking in the mid-high packs called for innovation in the subwoofer technology as well, otherwise these would not be integrated systems. With each of the GEO M Series systems, a companion sub is offered in the same footprint, presented as the arrayable MSUB12 for GEO M6, MSUB15 for GEO M10 and MSUB18 for GEO M12. Using a new very high-efficiency hybrid band pass sub design, the result is particularly articulate low end with a very high output level for the cabinet size. “Also one of our goals was to build the best ground-stacking solutions we’ve ever offered. The MSUBs can be deployed in omni and cardioid implementation, either in stacked or flown configurations.” The front and back rigging system are compatible so the MSUBs can be implemented ‘front to back’.

Deffarges maintains that cardioid in larger PA systems needs to be carefully considered. “When you take a sub on its own, it is totally omnidirectional, with -1 or -2dB attenuation at the back. There are great benefits from going cardioid in the subbass range because then you can get -12 or -15dB. But, if you want to do that in a main system, you need to build a box that is deep. And, given the diffraction of the box itself, if a box is omnidirectional at 30Hz, it starts being directional at 80 or 100 Hz so you typically have 6-8dB attenuation at the back just because of the natural attenuation of the box. SO…. the benefit of going cardioid is to go from -8 to -12 (just 4dB of attenuation) and this is typically for the sky! The system is flown so the benefit is mainly enjoyed by the birds, it’s not where the audience or the musicians are standing! It’s a lot of cost for not very much user benefit.”